Entirely handknit.

Would you hire a portrait painter to paint your house? A house painter to make a portrait of your pet? If it’s clear that these people have vastly different skillsets, even though they all work with “paint”, a wet medium of colour, then you may be ready to appreciate the shift that seems to be happening in the world of fibre and textiles. In short — I believe we need to recognize that fibre/textile works can be art, and should be supported as such. Whether or not this has always been true, support for textile activities as a viable craft is falling away in the modern age, and people seem to be engaging in it either as a pleasurable pastime or are dedicated medium of expression. As I’ve been struggling to try to capture the thought for this post (over the past months), I conclude that my hesitancy largely stems from the fact that I can’t tell if this means a glass half empty (are we losing our handmade textiles skills?) or half full (more of us can pursue it deeply without the drudgery of dependence). My thinking for this post started in September (2014), when Kate Davies posted a really fun blog entry about Monrospun sweater kits, with pre-knitted multicoloured yokes ( http://katedaviesdesigns.com/2014/09/21/yoke-in-a-bag/ ). She had some interesting points to make about how the (leisure) knitters of today live in a very different fibre world than, say, decades ago when such a kit would have been generally available. I immediately thought, “Yeah! things really have changed! Isn’t that odd?” and a number of things besides. But, it took a while (and lots of typing and peering at the screen) to figure out what it is that I think I have to say. Periodically, I would come across some other article or bit of information and thing, “Ooooh, that’s a piece of the puzzle!” and dump it into the draft post. But the puzzle pieces didn’t organize themselves into a coherent picture. Perhaps it would have been a quicker process if I was an expert in any of the areas discussed below, but I’m not — so take the rest of this post as my best effort to distill a bunch of thoughts on the (recent) evolution of small scale textile making. It’s my thinking — and understand that “your mileage may vary” as they say in car advertisements. (But, if you want to read something by someone who does know quite a lot about the evolution of human textile making, I can thoroughly recommend Elizabeth Wayland Barber’s “Women’s Work: the First 20,000 Years — Women, Cloth and Society in Early Times”). Briefly, it seems evident that things have changed a lot in the world of textiles and apparel construction, within living memory. When you take a step back and look at slightly longer timeframes, it’s clear that these changes are part of a larger trend. This is especially intriguing when you consider that the making of cloth and clothing has been central to human activity for an unimaginably long time. It’s not just that people knew how to do it: it’s what people had to do for a lot of their lives. Per Barber’s book, for women in early times, when you weren’t getting food or engaged in childcare, you were producing cloth. Even rich (royal) women spun. Cloth was used as a form of currency before there were coins and money. Spinning, weaving and sewing were essential life skills for women, at least until the industrial revolution. But, we live in interesting times — in most or all of the developed world, textile skills development is purely elective. Our clothing needs are met by industrial production. We are not quite at the conclusion of of small-scale textile/apparel making, but it seems close — or maybe it will find a viable future as an elective pastime.

Things have changed over time — and quickly, recently.

Back to Kate Davies’ post: not so long ago, people wanted to buy pre-knit colourful yokes for handknit sweaters. That is, they wanted (or needed) to knit their own sweaters, but were willing and able to buy their way out of knitting the most difficult part. Implicit in this is the fact that there were people who were able to do the yoke pre-knitting, presumably at some level of income that supported their skills. In the intervening few decades, those realities have shifted. Nice sweaters are more affordably bought than handmade, so mostly it’s only people who actually want to knit that are knitting their own. And, for them, the yoke is the fun part (rather than all that boring stocking stitch body, and getting stuck on “sleeve island” — hey, don’t talk to me about it! Icelandic yoked sweaters are the whole reason I learned how to knit!). And, while they are the ones with the necessary skills, these are not the people who are going to find it worth their while to knit yoke parts for someone else to incorporate in their sweater projects. So finding enough knitters who are skilled enough to knit the yoke pieces by hand, for a rate of pay that would make the kit viable, would be a real challenge, outside of developing economies. And, probably more importantly, the quality of commercially made sweaters today is such that they are not (always) embarrassing to wear. Kate’s post mentions that coordinated woven skirt kits were also available to go with the Munrospun sweaters, and she wondered if any of her readers had ever had any experience with them. I thought immediately of the sweater/skirt sets that used to (and may still) be available from Cottage Craft in St. Andrews(-by-the-Sea) in New Brunswick, Canada. From the comments on Kate’s blog post, I was not alone in that leap! Although Cottage Craft has had a rough time of late because of a dispute over the state of repair of their historic, wharf-based building, I dug up Stephanie Pearl-McPhee’s tale of visiting the shop and the sweater/woven fabric matches were still available as recently as 2011. ( http://www.yarnharlot.ca/2011/10/cottage_craft/ ). Having recently read Grace Helen Mowat and the making of Cottage Craft (Diana Rees with Ronald Rees), I understand that those sweater/skirt kits were a mainstay of Cottage Craft for decades. Cottage Craft was established in the early 1900’s, with a vision to create beautiful and local craft products (weaving, pottery, rug hooking). It was influenced by, and came at the tail end of, the Arts & Crafts movement. With industrialization, the need to make one’s own textiles was dwindling rapidly, and spinning wheels and looms were stored away in attics. What Mowat did was leverage the remaining skills and tools in the community, providing a way for people (e.g., farmers’ wives) to make extra income from the home while they collectively built up a reputation for quality crafts.

Now, you can’t afford handmade even if you want to

Today’s reality is different than the one Mowat tapped into. As it stands — we’ve gone from “machine made is available” to “machine made is as good as or better than handmade” in about a hundred years. Although there is still the odd spinning wheel or weaving loom tucked away in an attic, there really is not the skill base to use them to produce yarn or cloth at anything like scale, or for an affordable wage. Even if you had a preference for a hand made shirt, you likely could not afford to buy it; at the very least, you would have a hard time justifying the expense. In 2013, Eve Fisher wrote up an economic analysis of what it would cost, today, to make a shirt using pre-industrialisation techniques. From http://www.sleuthsayers.org/2013/06/the-3500-shirt-history-lesson-in.html :

When the Industrial Revolution began, it started with factories making cloth. Why? Because clothing used to be frighteningly expensive. Back in my teaching days I gave a standard lecture, which is about to follow, on the $3,500 shirt, or why peasants owned so little clothing.

(And, I see she’s updated the analysis — an even more depressing statistic in terms of weeks of labour: http://www.sleuthsayers.org/2015/01/is-time-money-or-is-money-time.html ). Okay, you can have a handmade shirt today without starting from fibre and spinning and weaving, but I think the point stands: it’s going to cost an order of magnitude more than and industrially-made shirt; perhaps more. Hmmm. People are no less capable of being skilled at handwork today than they were a century ago, but the motivation (and ability) to become so are undermined by the general expectation that every adult has a full time occupation, generally outside the home. So, a fibre occupation has to compete with the financial opportunities of modern day careers. If I try to figure the math from my own reality, this is what I get:

What I could charge for knitting a sweater (exclusive of materials) is more than a friend would be likely willing to pay, but still about what I can charge for an hour of my time, consulting. It’s not that I’m a greedy consultant — that’s just the reality of our times. But, I could only knit about 2 sweaters a week (if I did it for all the hours in a standard work week), and I can’t afford to live on 2 hours’ income per week.

Even if your numbers are different, it still works out to be very difficult to earn a living wage by knitting as a sole occupation in today’s developed world. I’m going to poke at that hypothesis some more, below.

Value judgement and quality

With any form of scaling up of process (forced labour, industrialization), complexity and quality of output drops, at least initially. In ancient times, women who wove for themselves and their own livelihood put extra effort to embellish their work. Once captured and forced to produce for others’ gain, that fell away. It wasn’t the lack of knowledge — lack of available resources, or time pressures, or whatever. Also with industrialization and increasing scale of production, the cost of production goes down, and goods can be sold more cheaply. So, needed goods may be less complex in design and of lower quality, but they are more readily acquired. The difference in cost to produce something in small scale puts a price to the incremental quality improvement of the handmade good of higher quality, meaning two things as long as there is a notable difference:

- People who can afford it will pay to have the small scale production goods

- Less rich people will continue to make their own

- as long as it doesn’t interfere with their livelihood — that’s their tradeoff

- as long as the cost of materials is less than the cost of the completed good sold commercially

- I.e., the individual maker discounts their own labour

Of course, the less notable the difference, the fewer people willing to pay for handmade or to make their own. If we look back, we can observe that, through the mid-20th century, women made a lot of their own clothing — sewing and knitting, chiefly from industrially made materials (woven or knit fabric, yarn). There were still people regularly making clothing for others — seamstresses, the people who knit the yokes for the Monrospun kits. But, as the century wore on, two trends reached important tipping points in the late 20th century:

- More women worked — sewing and knitting got in the way of their livelihood

- Industrially made clothing quality improved (in terms of wearability, durability and style)

Those two points made the incremental win of smaller, and also made it harder to make your own. And, mass market style became trendy (and affordable). Your jeans had to have a name, and not your name. Of course, inherent in the above text is an implicit assumption about what is “better”, as if handmade always is. It’s not really a fair assumption — there’s certainly lots of sloppy handmade work in the world, and also fine machined things. What I will admit is a certain sense of loss as we hand over our skills to machines and industrialization, even as I am no way advocating we all return to some (hardly) idyllic past way of producing things, at least for textiles (food, on the other hand… we should talk).

People can’t make a living off making handmade cloth or clothing

I suggested, above, that it’s difficult today to make a living wage by knitting. It’s a bold statement, and I’ll be honest and say that I have little data to back it up apart from the back-of-the-envelope figuring I did for my own sweater knitting reality. As always, it depends on your definition of “making a living”, and the exceptions prove the rule: Double Whale Handwoven Designs in Lunenburg, NS celebrated its 30th anniversary in May 2014, and Laura Fry who proudly decided to be a professional weaver in the 1970’s, has no doubt forgotten more than us amateurs can ever hope to know on the subject of making fabric. Most commonly, people who love fibre arts make a living off related things — indie yarn dyers, teaching (in person, online, DVDs), writing books, selling patterns for needlepoint — http://www.marketplace.org/topics/your-money/internet-taking-us-back-time-return-handmade-goods . Chrissie Freeth wrote about the challenges of making money as an artist, with fibre: http://dizziebhooked.wordpress.com/2014/10/26/making-a-living-from-art/.

A point of curiosity…

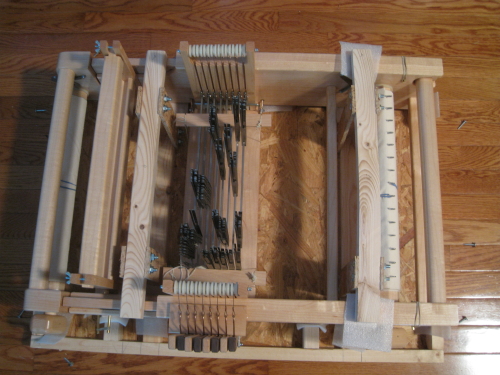

In the midst of all this, the industries producing textile-making tools are busy. Knitting machines (a bridge technology, popular for home use in the mid-1900’s as knitting went from handmade to industrially-produced) are fading away, as most companies have stopped production. But, older tools, such as spindles, spinning wheels, weaving looms, and every imaginable sort of knitting needle or crochet hook are still very much in production. (Some of them are made by woodworkers, who sought a way to make a living at their skilled manufacturing trade!). Here’s a point of curiosity:

Show me a person with 3 spinning wheels and a bevy of weaving looms, and I will show you someone with a fibre hobby. Show me someone making a living with fibre and I’ll show you a person with a single of any tool, well-worn and patched.

Let me unpack that a bit. People who are supported by salaries from modern-era employment are most likely to be in a position to spend money on pastimes. The capital cost of this equipment is significant, but not out of line with the sorts of things a modern-era employment lifestyle warrants — a loom costs less than a year of car payments, one exotic vacation, or a tricked-out TV/entertainment set up. You can get a nice spinning wheel, new, for the cost of a couple e-readers or a notebook computer (and the spinning wheel will have a useful life of considerably greater length!). You might have to think twice before spending the money, but it’s not outlandish. And, maybe you’ll upgrade, or add to the herd another year. If you look at used, you might suddenly be overtaken by OLAD (“obsessive loom acquisition disorder” 🙂 ) and then you start redecorating your home with fibre equipment. For a pastime, you really can’t justify the cost of the equipment by amortizing it across projects made — or else, I have some seriously expensive designer dishtowels I’ve woven on my loom 😉 . If fibre is your livelihood, though, you have chosen a lesser-income career, and you don’t have the option of such luxurious pastime tools. You do have to amortize the cost of the equipment somehow — so perhaps you can afford a new loom for every 2,000 dishtowels sold? That’s lots of wear — and patching.

Looking at scale

I’ve been talking mostly about individual hand-makers — spinners, weavers, knitters. Before we got to today’s level of massive scale industrialization, there was a whole level of mechanized but still small-scale production that flourished. That sort of small scale production was useful for dropping the costs of each step, while keeping the work relatively local. Last year, Tomorrow published a study of “local textiles”, looking at the possibility of revitalizing the textile industry in New Brunswick, Canada — the same province that featured Cottage Craft’s creation at the beginning of the last century. Tomorrow’s premise is that locally-made means higher quality, and that should merit the higher costs. Let’s take a look at today’s more prominent massive-scale textile production to get a sense of what that would compete with. PlanetMoney (NPR) did a story in which they tracked the making of T-shirts from start to finish. A fascinating story in its own right, it gives an inside view of that textile industry — pretty complex and extremely competitive. Cents matter. Yarn recipes are trade secrets. Check out the different types of yarn in the different commercially available garments with which you might be familiar: http://apps.npr.org/tshirt/#/machines . Look at the spinning machines operating in the video and think about hand work, or even small-scale production, competing with that. The cost of production difference is still an order of magnitude, at least — a $5 T-shirt or a $50 shirt? The Tomorrow study mentions Briggs & Little — the oldest woollen mill in New Brunswick. Its yarn is one of my favourites for making warm sweaters that wear well for years. (Hmm, I seem to only have one posted in my gallery. I have a couple others in my closet, and have made a few for DH, too). But, I’m not Briggs & Little’s traditional market. Cottage Craft and Briggs & Little worked collaboratively for decades — developing yarn colours and ultimately having a supplier-consumer relationship. That probably moved a fair bit of yarn, but didn’t do so much for making Briggs & Little a household name among today’s primary consumers of small-run yarn — handknitters. Another of my favourite sweater yarns, Mountain Mohair, is spun by the Green Mountain Spinnery in Vermont. I’ve visited both locations. The Spinnery is a much smaller setup, and was started more than a century later than Briggs & Little — but is probably better known in the handknitting world today. It really seems like there is a bifurcation of worlds — clothes come from industrial production, and small scale production serves the person dedicated to creating unique items.

How does this compare to other areas?

Food

Providing ourselves with food to eat is one of the few things that we, collectively, have been doing longer than making cloth. It, too, has seen massive industrialization since the mid- to late-1800’s, as we have gone from family-run farms to large mega-corp and mega-crop situations. It wasn’t just primary food production that started scaling up — it was also food packaging and sales. (For an intriguing insight into one part of that, I can heartily recommend “Chocolate Wars” by Deborah Cadbury (yes, that Cadbury)). Today’s options for feeding yourself commonly include:

- Cook your own meals, from ingredients [make your own clothes from purchased yarn/fabric]

- Buy pre-packaged meals and heat them at home [buy kits and assemble]

- Take out/restaurant [buy off the rack]

The pre-packaged meals have come a long way since the aluminum “TV tray” dinners of the 1950’s. I distinctly recall the day I had a pre-packaged pasta & sauce kit that was better than something I could make myself (and I’m not a bad cook!). Takeout and restaurant eating are commonplace for many in the US. In fact, the trend towards re-heating packaged foods and/or eating out is so strong that there are predictions that kitchens will disappear from homes of the future. (Have a look at this if you want to follow someone who’s delved into this question in more depth). We clearly have swung a lot closer to the last item on the list with clothing and textiles than with food, in roughly the same timeframe. I wonder why that is? Are the economics different? Perhaps because no food (ingredient or packaged) lasts forever? Clothing is much more optional (in some cultures more than others :^) ), but food is necessary? How we feel, and our longer term health is much more dependent on food than cloth?

Painting (artistry)

Unlike producing food and clothing, the making of art has always been an elective activity. Sure, artists are driven, often compelled to produce their works, and societies are somehow measured by the quality of art that they produce. However, failure to produce art does not kill you, at least not the way failure to produce or find food does in the matter of days (and clothing even quicker, depending on the climate). A thousand years ago, if you wanted to decorate a church (to teach the assembled parishioners or simply to be impressive), architecture, painting and sculpture were your tools. As recently as a couple hundred years ago, if you wanted a “likeness” of someone, a portrait was painted. In the intervening time, the act of painting has not been taken over by mechanization, but imagery is now often produced by photographs or digital graphics. But, as a society, we still value paintings — as artwork. Not everyone has an appreciation for them, or would spend money to have a painting in their home. It’s probably harder to make a living as an artistic painter now than ever before. But, we accept it as an elective activity that produces things that are valued for their beauty or power, rather than a strictly functional purpose. We don’t rate paintings based on the cost of the materials and number of hours to produce them. We value them based on their expression.

So, is the glass half full or half empty?

It does bothers me that it’s so difficult to make a living directly with fibre — and not just because I can’t figure out how I can personally spend my life playing with fibre and holding up my end of the household income budget. If it’s that hard to make a living at making textiles, then it seems to me that very few people can afford to spend the significant part of their life necessary to become truly expert at the underlying skills. Of the people who knit or weave in their spare time (i.e., not making a living at it), the percentage of them who are spending large quantities of time doing samplers and other forms of skill-building drills is vanishingly small. I worry that the fate of our (collective) ability to produce very high quality, truly beautiful textiles is hanging in the balance, and we’ve gone from a situation of everyone being a potential master craftsperson to the point of potentially losing the knowledge and know-how in a matter of a few generations. But, on the other hand, we are indeed freed from the drudgery of having to produce our own yarn, fabric, and textiles. People can engage in the activity if and as they like to. And, clearly, that doesn’t have to mean subpar results. If you haven’t, you really must look at the fundamentally awesome work of Tien Chiu. She took up weaving, decided to weave the fabric for her own wedding dress… and then designed and sewed it. And, it wasn’t just any old dress — it’s stunning, and now it is housed in the American Textile Museum. She did all of that while working a fulltime job in another field entirely. Makes me tired just to think about it :^) . Either way – it seems to me that it’s important that we get to valuing textile works properly. Art is different from painting houses — art is elective, expressive, and something that someone brought into the world because they wanted to. We value art for the creative expression it is, not just the functional utility it might provide. Maybe it’s time to apply the same rationale to at least some textile creations.