I haven’t had a lot of time for machine knitting over the last few

months (something to do with having to be in the same place as the

knitting machine for a chunk of time?!), and when I have sat down at

the machine, it hasn’t been a uniformly positive experience.

For example, I sat down the other day and cast on 166 stitches for the

back of a cardigan/jacket I started making last fall. I’ve done

the left & right front pieces and “just” need to do the back and

sleeves. I really didn’t get very far with it: the carriage

practically jammed on the first knit row, and by the second, all kinds

of stitches were leaping off the needles. Taking a closer look, I

realized that a number of needles had bent latches: they needed

to be replaced.

How many needles? Well, this many…

How does that happen? Well, I guess it’s sort of like learning to

drive standard — if you don’t know what you’re doing, you’re bound to

cause some wear and tear on the parts. Every time the carriage

jams or is very stiff to run across the needle bed, it’s likely that

needles are getting bent. I’m certainly hopeful that I’ll be

replacing fewer as time goes by and I get more experienced!

What do you do if you don’t have enough spare needles? Well, I

finally broke down and ordered a serious whack of spare needles (50 for

each bed). In the meantime, I pulled some of the needles

from the left and right edges of the machine to replace the bent ones

in the middle 166.

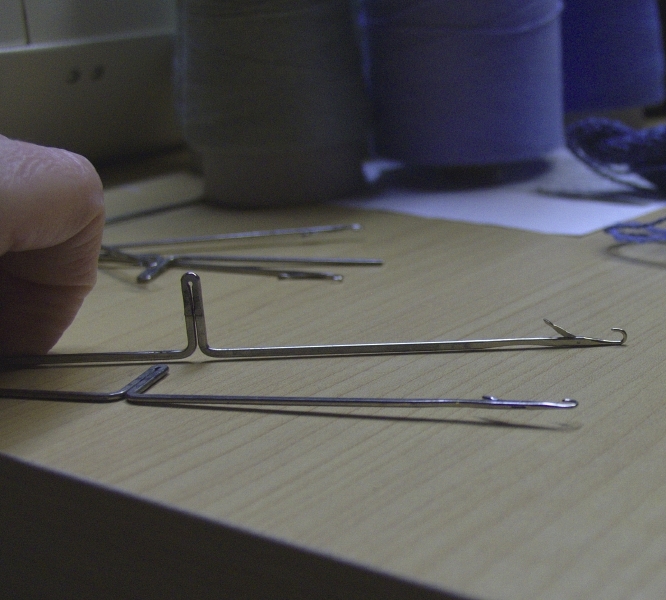

How bent is bent? I guess I’d ignored/been in denial about the

problem for a while. But, finally, the seven I pulled suffered

primarily from bent latches — they would not open fully, as is the

case for the needle in the background in this next picture — the latch

is as open as it will go, but it should flatten all the way down to the

stem. Another failure mode is that the needle gets bent sideways,

as you can see in the foreground needle below (it’s not lying flat on

the table).

After replacing the 7 needles, with some trepidation I cast on my 166

stitches once more, and passed the carriage cautiously (and

smoothly!) across the needle bed…

Hurray! That’s 2324 happy little stitches a-hanging from the main

bed! And, if ever you *doubted* the fun of machine knitting,

completing a couple thousand stitches in a matter of moments will

convince you!

Probably one of the reasons for the bent needles on the machine is that

I’ve been struggling to find the right yarns to use with the standard

gauge machine. It was (is) hard to get used to just how fine a

yarn the standard gauge machine uses. Essentially, it’s happy

with laceweight yarn. But, I kept doggedly trying yarns that I,

as a hand knitter, considered “fine”, and they just were too thick for

the machine.

Well, too thick for *that* machine. Not too thick for *this* one

🙂

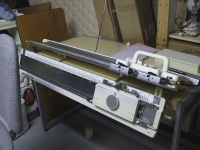

A while back, I found this Studio SK890 on eBay. It’s a *chunky*

gauge machine. That means the needle pitch is 9.0mm (to the

standard machine’s 4.5mm needle pitch), and it has 110 needles on the

bed (to the standard machine’s 200).

As I observed a while ago — knitters fall into exactly one of the

following categories:

- have no knitting machines

- have one knitting machine they don’t use

- have several knitting machines that do get used 🙂

At two machines, I really am just a beginner…